American Owned & Operated

Esco Optics is a leading manufacturer of custom and catalog optics, precision optical components, and ITAR optics in the United States.

Posted by Steve Rowe on

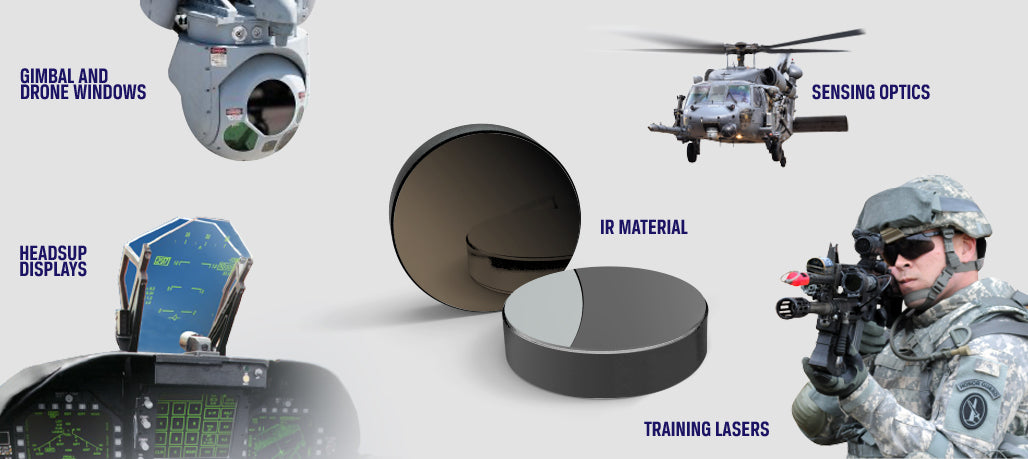

In the defense sector, optics must withstand extreme conditions including harsh climates, intense vibrations, and rigorous handling. Also, defense optics must extend beyond the boundaries of the visible spectrum into the infrared (IR), enabling military personnel to navigate their surroundings effectively in low-light or nighttime conditions. Some key applications of infrared optics in the military include: Night Vision Devices, Target Acquisition and Tracking, Guidance Systems for Munitions, Camouflage Detection, Pilot Vision in Low Visibility, Perimeter Security, Surveillance and Reconnaissance.

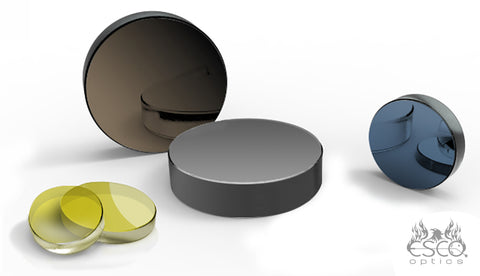

Materials used in defense and sensing optics are selected based on their transmission in ranges for IR capabilities and overall durability such as: IR fused silica, Silicon, Germanium, Sapphire, Zinc Sulfide and Zinc Selenide.

For example, germanium exhibits a notable combination of the highest refractive index and minimal optical dispersion. Its inherent hardness and high-density characteristics make it particularly well-suited for infrared applications that demand resilient optics. Meanwhile, sapphire is an excellent choice for harsh environments due to its exceptional hardness, ranking just below diamonds on the Mohs scale. Its hardness ensures resistance to scratches and abrasions, making sapphire an ideal material for optics that require long-lasting durability in various applications.

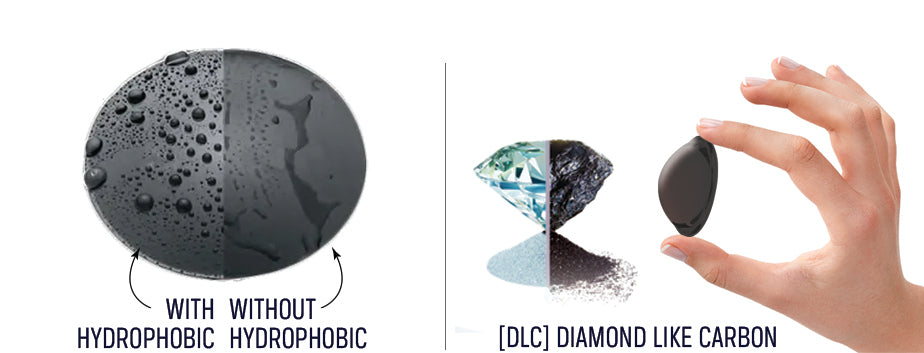

Regardless of whether your component is flat, spherical, or prism-shaped, your application may need a thin film coating to protect, reflect or filter light. Hydrophobic coatings aid in keeping visions systems clear by repelling water and preventing the formation of water droplets or fog on optical surfaces. This is particularly beneficial in applications where maintaining clear vision or imaging is essential. A Diamond-Like Carbon (DLC) optical coating offers exceptional hardness and durability, providing robust protection against scratches, abrasions, and wear. We work with our customers to provide extensive testing protocols to ensure that products can be trusted in critical situations. To learn more about optical coatings and the cost we have a brief article covering the most common questions and specifications.

Regardless of whether your component is flat, spherical, or prism-shaped, your application may need a thin film coating to protect, reflect or filter light. Hydrophobic coatings aid in keeping visions systems clear by repelling water and preventing the formation of water droplets or fog on optical surfaces. This is particularly beneficial in applications where maintaining clear vision or imaging is essential. A Diamond-Like Carbon (DLC) optical coating offers exceptional hardness and durability, providing robust protection against scratches, abrasions, and wear. We work with our customers to provide extensive testing protocols to ensure that products can be trusted in critical situations. To learn more about optical coatings and the cost we have a brief article covering the most common questions and specifications.

Recognizing the diverse needs of the defense and sensing industry, Esco Optics offers a range of customizable solutions whether the application is a fighter jet heads-up-display, sighting systems for a next generation tank, or laser training system. We can quickly adapt our catalog optics for rapid prototyping, and work with our suppliers to develop specialized coatings or solutions for specific mission requirements. Working closely with our clients, we provide tailor-made solutions that meet and exceed expectations.

Esco is ITAR registered and able to accommodate small and large optical fabrication from visible to UV to IR spectrums while demonstrating a commitment to pushing the boundaries of innovation. With a rich history dating back to 1955, Esco Optics has evolved into supplying state-of-the-art optical components to DoD, and defense contractors worldwide. Contact our sales engineers today to get started.

Esco Optics is a leading manufacturer of custom and catalog optics, precision optical components, and ITAR optics in the United States.

As the leader for military and defense optics in the United States, Esco Optics adheres to the International Traffic in Arms Regulations.

ITAR registered and compliant, Esco manufactures ITAR optics for all of its customers with the strictest confidentiality.