American Owned & Operated

Committed to supporting American industry and ensuring the highest-quality production standards.

Posted by Steve Rowe on

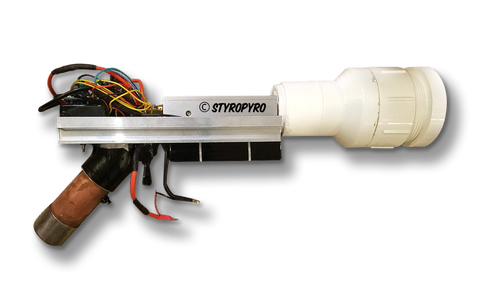

We recently provided our good friend and YouTuber, Styropyro (aka Drake Anthony) with a set of Infrared (IR) lenses for his handheld death ray build. We believe it’s quite impressive. Please click here to view the full video. Most people understand the use of infrared wavelength applications such as night vision equipment, however, following Styropyro's build we wanted to demystify some common thoughts on IR transmission and materials. There are many materials that perform well in the infrared spectrum. So how do you choose which is best?

The most common optical glasses for the IR spectrum are calcium fluoride, fused silica, germanium, magnesium fluoride, potassium bromide, sapphire, silicon, sodium chloride, zinc selenide, and zinc sulfide. The table below outlines some of the specific reasons you might choose one over the other.

The most common optical glasses for the IR spectrum are calcium fluoride, fused silica, germanium, magnesium fluoride, potassium bromide, sapphire, silicon, sodium chloride, zinc selenide, and zinc sulfide. The table below outlines some of the specific reasons you might choose one over the other.

| IR Material Attributes | ||||||

|---|---|---|---|---|---|---|

| Name | Refractive Index (nd) |

Abbe Number (vd) | Density (g/cm3) |

CTE (x 10-6/°C) |

dn/dT (x 10-6/°C) |

Knoop Hardness |

| Calcium Fluoride (CaF2) | 1.434 | 95.1 | 3.18 | 18.85 | -10.6 | 158.3 |

| Fused Silica (FS) | 1.458 | 67.7 | 2.2 | 0.55 | 11.9 | 500 |

| Germanium (Ge) | 4.003 | N/A | 5.33 | 6.1 | 396 | 780 |

| Magnesium Fluoride (MgF2) | 1.413 | 106.2 | 3.18 | 13.7 | 1.7 | 415 |

| Potassium Bromide (KBr) | 1.527 | 33.6 | 2.75 | 43 | -40.8 | 7 |

| Sapphire | 1.768 | 72.2 | 3.97 | 5.3 | 13.1 | 2200 |

| Silicon (Si) | 3.422 | N/A | 2.33 | 2.55 | 1.60 | 1150 |

| Sodium Chloride (NaCl) | 1.491 | 42.9 | 2.17 | 44 | -40.8 | 18.2 |

| Zinc Selenide (ZnSe) | 2.403 | N/A | 5.27 | 7.1 | 61 | 120 |

| Zinc Sulfide (ZnS) | 2.631 | N/A | 5.27 | 7.6 | 38.7 | 120 |

On Styropyro’s build we recommended using low OH, IR grade Fused Silica because of its optical quality, range of transmission and ability to accommodate a wide variety of final configurations. IR grade fused silica is specifically manufactured to remove OH impurities thus offering substantially higher transmission over UV grade fused silica up to 3.5 microns. It also has a high resistance to thermal shock and excellent homogeneity, making it a cost-effective option when compared to other IR materials. For many instrument manufacturers, it is an ideal choice for applications including process control and inspection for machine vision, high-resolution SWIR imaging, as well as, remote sensing…and of course a homemade death ray laser.

|

Optimum Transmission Range: |

Ideal Applications: |

|

250 nm - 3.6 µm |

Superior optical quality and IR transmission |

Additionally, we have a number of resources available that discuss optical properties and how to choose them available on our website. Contact an Esco representative to discuss your IR application and requirements. We’d be happy to assist.

Links:

Technical Series: Optical System Design

Optics University: Refractive Index

Need a custom optic?

Get a fast quote from us GET A QUOTE

Committed to supporting American industry and ensuring the highest-quality production standards.

Esco Optics proudly manufactures precision optics for all branches of the armed forces land, sea, air and space.

Esco manufactures compliant ITAR optics for all of its customers with the strictest confidentiality.

Dedicated to fostering connections, collaboration, and innovation across the optics manufacturing industry.