American Owned & Operated

Committed to supporting American industry and ensuring the highest-quality production standards.

Posted by Steve Rowe on

Today’s topic is prototypes versus production and associated cost implications. This is something I have dealt with my entire career, and I'm going to do my best to explain processes and what cost drivers exist when processing low-quantity prototypes versus full production runs.

Whether your optics are 0.5" or 22.0", making one of anything takes skill and time. I know everyone wants their packages the next day, just like Amazon. Unfortunately, precision optics manufacturing isn't at that speed yet. I can say that the shop at Esco can be nimble in production depending on the request and more on that later. While prototype manufacturing creates a functional and often one-of-a-kind model of a product, the primary goal is focused on testing and validating the design, functionality, and performance of the product before moving to mass production. Production manufacturing, on the other hand, is the phase where products are manufactured on a larger scale to meet market demand. The goal here is to produce consistent, high-quality products efficiently and cost-effectively.

At Esco, we have flat/plano and spherical capabilities, and I will start with flat which has more options. For very low quantities you can process 1 part using a single-sided method. In this process, you grind/polish one side, flip it over and then do the other side. It can be difficult to make the surfaces precisely parallel with this process, which can negatively affect transmitted wavefront error (TWE). Using a single sided process, at typical non-precision TWE between 2-5 waves can easily be polished over the clear aperture (CA). However, as a customer if you were to order 3-5 parts, then a “double-sided” grind and polish makes more sense. In double-sided polishing, both surfaces of the glass are polished simultaneously. This results in a highly uniform thickness and parallel surfaces on both sides. Parts would come out easily < 20 arc seconds parallel, and more likely < 10 arc seconds, producing a TWE of < 1 wave, and likely in the 0.50 wave range over the full CA.

Our double-sided department is set up to optimize efficiencies. We have small, medium, and large machines allowing us to satisfy a customer with a small quantity order without interrupting our manufacturing queue on our larger production runs. The medium and large machines handle a good portion of our production work. Our large capacity polishers can process multiple 200 mm diameter optics with exceptional accuracy.

Now, we shift across the shop to the lens department which handles all our spherical optics. I am only going to cover processing traditional and acylinder lenses. For aspherical and freeform optics, I will dive into how we manufacture those components in another post. Our lens department uses OptoTech and OptiPro machines, which are both extremely consistent and reliable. Like most R&D projects, your time is spent working out the most efficient steps to reach the final product. The first few pieces can take a significant amount of time. Once finalized, the production run gets progressively more cost-effective in volume as that time is spread out over the total of components.

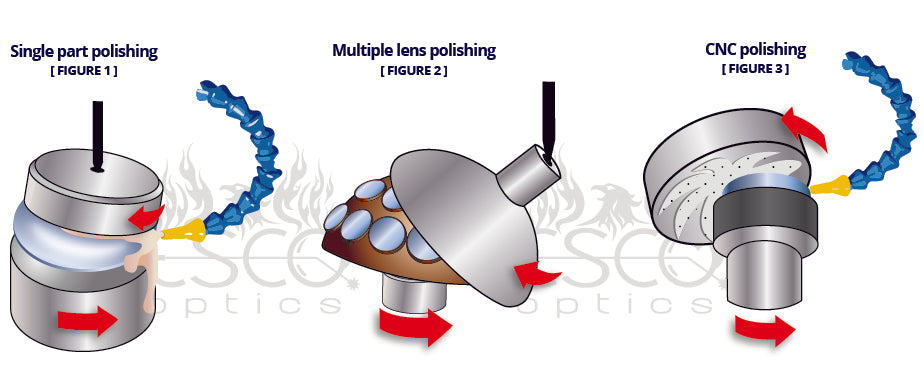

A CNC machine will remove the majority of material. After the lens is generated and fine ground, it undergoes polishing. Whether convex or concave your options are generally the same. You can polish a single part in process called pitch polishing need. [fig.1] The polishing tool is the inverse of the shape of the lens. Pitch is applied to the tool and is a layer between the tool and optic. A slurry of polishing compound is pumped in and slowly polishes the rough surface smoothly. Multiple lens polishing is used when you can mount several components with the same radii to polish together [Fig. 2]. Lastly, figure 3 Shows a CNC pad polishing technique using cerium oxide. This process is precisely computer controlled where to hit exact specification targets. Depending on the fabrication method, the right tooling can be crucial for the project. Esco has a full library of lens tools to support a wide variety of optical components over our 65+ year history.

Additionally, Esco has design tools that can help you with your spherical optics. Our online free optical calculator can assist you with formulas to generate your lens and we also have a whole series of blog posts dedicated to lenses and how they work.

Working with an optical manufacturer that can provide both spherical and plano optics is a big advantage for our customers. Whether you have a lens system or a custom pressure window, you are interacting with the same company that understands your needs. Esco has a rich history starting in the mid-1950s, but in today's world, our vertical integration keeps us nimble. Our dedication and laser sharp focus on customer needs, combined with our passion for building long-lasting relationships is our recipe for success.

Contact us today to discuss your next small or large project.

Committed to supporting American industry and ensuring the highest-quality production standards.

Esco Optics proudly manufactures precision optics for all branches of the armed forces land, sea, air and space.

Esco manufactures compliant ITAR optics for all of its customers with the strictest confidentiality.

Dedicated to fostering connections, collaboration, and innovation across the optics manufacturing industry.