American Owned & Operated

Committed to supporting American industry and ensuring the highest-quality production standards.

Posted by Bill Hill on

We welcome our readers back to our continuing technical series on the Concepts of Light and Optics. So far we’ve examined the nature of light and how it propagates, the principles of refraction and dispersion, material characteristics, interferometry, as well as, the fundamental specifications of plano optics. Building on all of these discussions, we now move on to a topic that is at the heart of optical fabrication – lenses.

Lenses represent the workhorse of most optical systems. Properly designed and manufactured, these essential elements manipulate light, allowing scientists to examine everything from the minute details of cellular structure using optical microscopy, to the vast overall structure of the universe using powerful ground-based and orbiting telescopes such as the Hubble.

As the combined topic of lens characteristics would produce an article of great length, we’ve decided to separate it into three sections. The first, which we will discuss today, will cover the different types of lenses and their intended purpose. In subsequent articles we will then discuss the terminology and basic equations used to characterize lenses, as well as, the types of aberrations they are designed to minimize. Finally, we’ll examine the specifications used by optical designers and fabricators to precisely define the surface figure and performance requirements.

If you recall from our discussion of refraction and dispersion, all optical materials influence light in different ways. The refractive index defines the manner in which light will bend as it enters a new medium while the dispersive index more precisely defines how each individual wavelength (or frequency) will behave. Optical engineers choose materials based on these principles, however, this is only the first step in the design process. More importantly, they then must decide on the appropriate physical shape of an optic in order to achieve its desired effect. In essence, it the final curvature of a lens in tandem with its optical properties that ultimately determines how it influences light.

All lenses adhere to one of two basic principles as a function of their shape – they either focus or disperse light. As such, lenses which focus light are called positive lenses while those that disperse light are called negative lenses. As the purpose of this article is to first introduce the basic types of lenses, let us now examine the most common lens configurations.

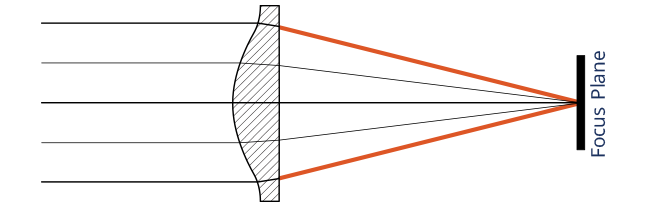

As their name implies, both plano-convex and biconvex lenses have either one or two surfaces with positive spherical contours. Regardless of design, the thickness at the edge of the lens is always less than the thickness at the center. These lenses are used to focus light to a pre-defined point based on the amount of curvature of their surfaces. In the case of a plano-convex design, one surface remains flat while the second has a positive curve and for biconvex lenses, both surfaces are positively curved. In practical use, plano-convex lenses are most commonly employed where the object being imaged is far away from the lens. In optical terms this is called infinite conjugate and an example of this circumstance is focusing light from a distant object such as a star. Biconvex lenses are also used to focus light but are best employed where the object being imagined is much closer to the lens. This is called finite conjugate and microscopy is a practical example.

Plano-concave and biconcave lenses can be thought of as the opposite of plano-convex and biconvex lenses. Having negative curvature means that rather than focusing light, these optical elements disperse the incident energy. By design, the thickness at the edge of the lens is always greater than the thickness at the center. These optics are often called beam expanders and the below examples demonstrate how light traveling through them is dispersed from its original path.

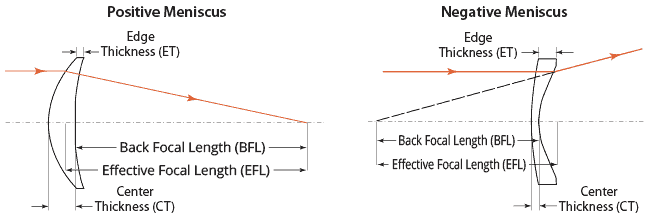

Meniscus lenses have one surface that is concave and one that is convex. Depending on their contour, these optics can be either positive or negative. If the curvature of the convex side is steeper than the concave side, the resulting light path is refracted towards a predetermined focal point. Conversely, if the concave curvature is greater than the convex side, the light is then dispersed. Negative meniscus lenses can therefore also be thought of as beam expanders.

Aspheric lenses differ from all other optics in regards to their shape. As shown above, typical lenses are designed to have spherical contours. Regardless of their intended use, their convex or concave shape follows a consistent regular path across the surface of the lens. In the case of aspheres, optical designers intentionally create surface contours that no longer adhere to this standard type of curvature. The resulting shape allows a single lens to refract light in a manner that otherwise would require the use several lenses placed in series. Using aspheres in this manner typically reduces both the size and overall weight of an integrated lens system, however, these benefits must be weighed against the cost to manufacture such highly complex surface contours. Aspheres are more difficult to fabricate and measure and are therefore more expensive than traditional lenses. As they can be designed with either convex or concave surfaces, aspheres can therefore be either positive or negative in their refraction of light.

Cylinder lenses are unique in their design and function. The easiest way to conceptualize their shape is to first think of a circular rod. Slicing off a section of the rod along its length produces a lens with curvature in a single direction. This one-directional shape allows optical designers to focus light along a line instead of a single point. In practical use, they are often employed in scanning systems where a linear cross section allows for faster retrieval of data, such as barcode readers and inspection equipment.

Acylinders combine the line-focus of a cylinder lens with the benefits of an aspherical design. They assist in reducing what opticians call spherical aberration (which will be covered more in-depth in our next article), while allowing the resulting focused line to be thinner and more precise.

As shown from the different examples, lenses come in a wide variety of configurations. By combining a specific optical material with various types of surface contours, light can be harnessed, steered and manipulated for a given purpose. Esco Optics manufactures all of the above types of lenses using both traditional pitch polishing techniques, as well as, CNC-guided spherical and free-form generation equipment. In addition, all metrology to certify the surface figure and shape is performed in-house.

If you need a quote for a custom or modified catalog optic start here.

In our next article we will build upon these basic lens shapes by discussing the terminology and equations opticians use to define how a lens will function, i.e. focal length, radius of curvature, etc. We will also present various optical phenomena such as astigmatism, spherical aberration and coma, and relate how opticians employ various lens designs to minimize and eliminate these anomalies.

Concepts in Light and Optics – Lenses – Part 2

Concepts in Light and Optics – Lenses – Part 3

Committed to supporting American industry and ensuring the highest-quality production standards.

Esco Optics proudly manufactures precision optics for all branches of the armed forces land, sea, air and space.

Esco manufactures compliant ITAR optics for all of its customers with the strictest confidentiality.

Dedicated to fostering connections, collaboration, and innovation across the optics manufacturing industry.